-

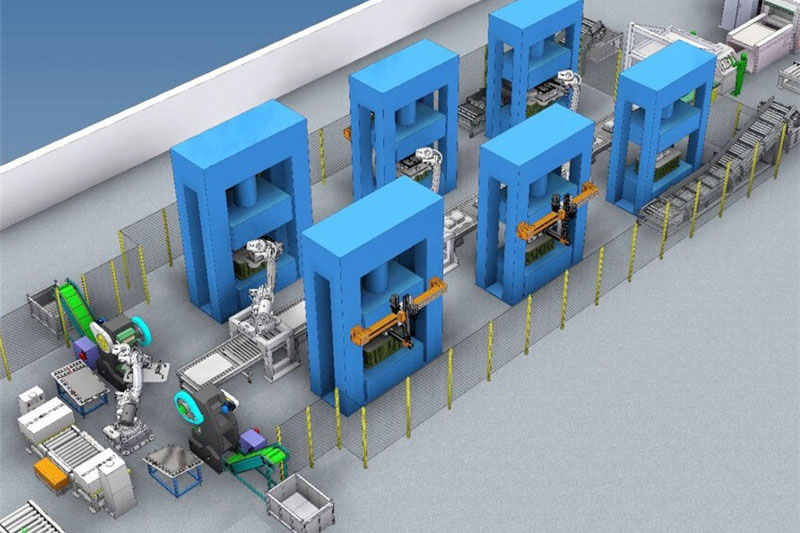

stainless tšepe metsi sink tlhahiso line

Mohala oa tlhahiso ea sink ea tšepe ea tšepe e sa hloekang ke mohala oa boiketsetso o kenyelletsang lits'ebetso tse joalo ka ho phutholla lithapo tsa tšepe, ho seha le ho hatakela ho etsa lisinki. Mohala ona oa tlhahiso o sebelisa liroboto ho nkela mosebetsi oa matsoho sebaka, e leng se lumellang ho phetheloa ka mokhoa o ikhethileng oa ho etsa sink.

Mohala oa tlhahiso ea sink ea tšepe ea tšepe e sa hloekang e na le likarolo tse peli tse kholo: lisebelisoa tsa thepa le setsi sa setempe sa sink. Likarolo tsena tse peli li kopantsoe ke yuniti ea phetisetso ea thepa, e thusang ho tsamaisa thepa lipakeng tsa tsona. Setsi sa phepelo ea thepa se kenyelletsa lisebelisoa tse kang li-coil unwinders, li-laminator tsa lifilimi, li-flatteners, li-cutters le li-stackers. Setsi sa phetisetso ea thepa se na le likariki tsa phetisetso, likhoele tsa ho bokella thepa, le mela e se nang letho ea polokelo ea pallet. Sehlopha sa setempe se na le mekhoa e mene: ho itšeha ka mahlakoreng, ho otlolla ka sehloohong, ho otlolla ha bobeli, ho fokotsa moeli, ho kenyelletsang tšebeliso ea mechine ea hydraulic le automation ea robot.

Bokhoni ba tlhahiso ea mohala ona ke likotoana tse 2 ka motsotso, ka tlhahiso ea selemo le selemo ea likotoana tse ka bang 230,000.

-

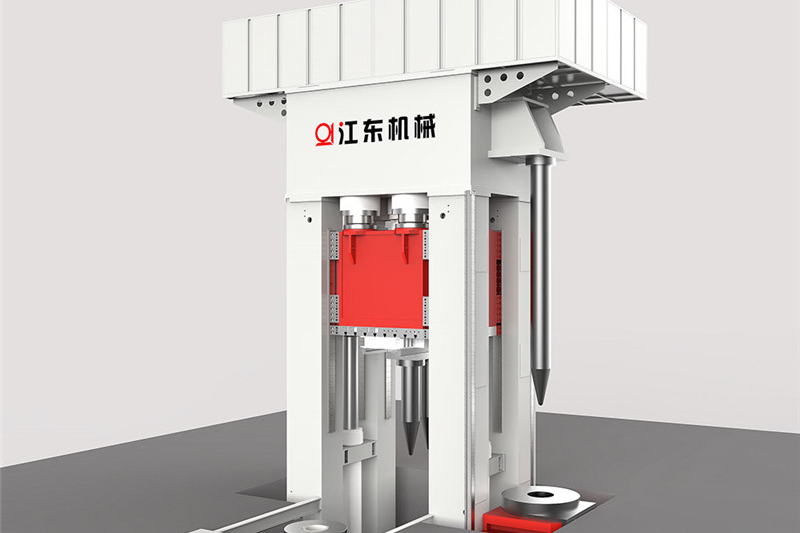

SMC/BMC/GMT/PCM Composite Molding Hydraulic Press

Ho netefatsa taolo e nepahetseng nakong ea ts'ebetso ea ho bopa, mochini oa khatiso oa hydraulic o na le sistimi e tsoetseng pele ea servo hydraulic control system. Sistimi ena e ntlafatsa taolo ea maemo, taolo ea lebelo, taolo ea lebelo la ho bula ha micro, le ho nepahala ha paramethara ea khatello. Ho nepahala ha taolo ea khatello ho ka fihla ho ± 0.1MPa. Li-parameter tse kang boemo ba li-slide, lebelo le theohelang, lebelo la ho tobetsa pele, lebelo la ho bula ha micro, lebelo la ho khutla, le maqhubu a ho qeta nako li ka behoa le ho lokisoa ka har'a mefuta e itseng ea skrine. Sistimi ea taolo e boloka matla, e nang le lerata le tlase le tšusumetso e nyane ea hydraulic, e fanang ka botsitso bo phahameng.

Ho rarolla mathata a tekheniki joalo ka meroalo e sa leka-lekanang e bakoang ke likarolo tse entsoeng ka asymmetric le ho kheloha ha botenya lihlahisoa tse tšesaane tse kholo, kapa ho finyella litlhoko tsa ts'ebetso tse kang ho roala ka hlobo le ho senya ka tsela e ts'oanang, mochine oa khatiso oa hydraulic o ka ba le mochine o matla oa hang-hang oa likhutlo tse 'nè. Sesebelisoa sena se sebelisa li-sensor tsa phalliso e nepahetseng haholo le li-valve tsa servo tse arabelang khafetsa khafetsa ho laola ketso ea tokiso ea synchronous ea li-actuator tsa li-cylinder tse nne. E fihlella ho nepahala ha maemo a holimo a likhutlo tse nne ho fihla ho 0.05mm tafoleng eohle.

-

LFT-D faeba e telele e matlafalitsoeng ka thermoplastic compression e otlolohileng ea mochini oa tlhahiso

LFT-D fiber e telele e matlafalitsoeng ka thermoplastic compression direct molding line line ke tharollo e pharaletseng ea ho etsa thepa ea boleng bo phahameng ea boleng bo phahameng. Mohala ona oa tlhahiso o na le sistimi e tataisang ea likhoele tsa khalase, mochini o tsamaisang motlakase o potlakileng oa hydraulic le setsi sa taolo se bohareng.

Ts'ebetso ea tlhahiso e qala ka ho feptjoa ha fiber ea khalase ka har'a extruder, moo e khaoloang ebe e fetisetsoa ka har'a sebopeho sa pellet. Joale li-pellets li futhumatsoa 'me ka potlako li bōptjoa ka mokhoa o lakatsehang ho sebelisa mokhoa oa ho sebetsana le thepa ea robotic le mochine o potlakileng oa hydraulic. Ka matla a selemo a tlhahiso ea 300,000 ho 400,000 lichapo, mohala ona oa tlhahiso o tiisa tlhahiso e phahameng.

-

Thepa ea Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM).

Thepa ea Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) ke tharollo e tsoetseng pele e ntlafalitsoeng ka tlung bakeng sa tlhahiso ea likarolo tsa boleng bo holimo tsa carbon fiber. Mohala ona o felletseng oa tlhahiso o na le litsamaiso tsa boikhethelo tsa preforming, mochini oa khatiso o ikhethileng oa HP-RTM, sistimi ea ente ea resin e phahameng ea khatello ea HP-RTM, liroboto, setsi sa taolo ea mohala oa tlhahiso, le setsi sa boikhethelo sa mochini. Sistimi ea ente ea resin ea khatello e phahameng ea HP-RTM e na le sistimi ea metering, sistimi ea vacuum, sistimi ea taolo ea mocheso, le sistimi ea lipalangoang le polokelo ea thepa e tala. E sebelisa mokhoa oa ente e nang le khatello e matla, e sebetsang ka likarolo tse tharo. Mochine oa khatiso o khethehileng o na le tsamaiso ea likhutlo tse 'nè, e fanang ka ho nepahala ho tsotehang ha 0.05mm. E boetse e na le bokhoni ba ho bula li-micro-opening, e lumellang hore ho be le lipotoloho tse potlakileng tsa tlhahiso ea metsotso ea 3-5. Thepa ena e nolofalletsa tlhahiso ea batch le ts'ebetso e feto-fetohang ea likarolo tsa carbon fiber.

-

Metal extrusion/hot die forging hydraulic press

The Metal extrusion/hot die forging hydraulic press ke theknoloji e tsoetseng pele ea tlhahiso bakeng sa ts'ebetso ea boleng bo holimo, e sebetsang hantle, le e tlaase ea tšebeliso ea lisebelisoa tsa tšepe tse nang le lisebelisoa tse fokolang kapa tse se nang letho. E fumane ts'ebeliso e pharaletseng liindastering tse fapaneng tsa tlhahiso tse kang likoloi, mechini, indasteri e bobebe, sefofane, ts'ireletso le lisebelisoa tsa motlakase.

The Metal extrusion/hot die forging hydraulic press e etselitsoe ka ho khetheha bakeng sa extrusion e batang, extrusion e futhumetseng, forging e futhumetseng, le lits'ebetso tsa ho etsa mochini o chesang, hammoho le ho phethela ka nepo likarolo tsa tšepe.

-

titanium alloy superplastic e etsang hydraulic press

Mochine oa khatiso oa Superplastic Forming Hydraulic ke mochine o khethehileng o etselitsoeng ho etsoa ha lisebelisoa tse rarahaneng tse entsoeng ka thepa e thata ka ho fetisisa e nang le mocheso o moqotetsane oa deformation le khanyetso e phahameng ea deformation. E fumana ts'ebeliso e atileng liindastering tse joalo ka sefofane, sefofane, sesole, ts'ireletso le seporo se lebelo le holimo.

Mochine ona oa khatiso oa hydraulic o sebelisa superplasticity ea thepa, joalo ka li-alloys tsa titanium, lialloys tsa aluminium, li-alloys tsa magnesium, le li-alloys tsa mocheso o phahameng, ka ho fetola boholo ba lijo-thollo tsa thepa e tala hore e be boemo bo phahameng ka ho fetisisa. Ka ho sebelisa khatello e tlase haholo le lebelo le laoloang, mochine oa khatiso o fihlella deformation ea superplastic ea thepa. Ts'ebetso ena ea phetoho ea tlhahiso e nolofalletsa tlhahiso ea likarolo tse sebelisang meroalo e menyenyane haholo ha e bapisoa le mekhoa e tloaelehileng ea ho etsa.

-

Mochine oa khatiso oa hydraulic oa mahala

Free Forging Hydraulic Press ke mochini o ikhethileng o etselitsoeng lits'ebetso tse kholo tsa mahala tsa mahala. E thusa ho phethela lits'ebetso tse fapaneng tsa ho qhekella joalo ka ho lelefatsa, ho ferekanya, ho phunya, ho holisa, ho taka bar, ho sotha, ho kobeha, ho sisinyeha le ho poma bakeng sa tlhahiso ea li-shafts, lithupa, lipoleiti, li-discs, mehele le likarolo tse entsoeng ka libopeho tse chitja le tse sekoere. E na le lisebelisoa tse tlatselletsang tse joalo ka mechini ea forging, sistimi e sebetsanang le thepa, litafole tsa lintho tse rotary, li-anvils, le mekhoa ea ho phahamisa, mochine oa khatiso o kopanya ka mokhoa o se nang seam le likarolo tsena ho phethela tšebetso ea ho qhekella. E fumana lits'ebetso tse pharaletseng liindastering tse kang sefofane le sefofane, kaho ea likepe, tlhahiso ea matla, matla a nyutlelie, metallurgy le petrochemicals.

-

Light Alloy Liquid Die Forging/semisolid forming Line Line

The Light Alloy Liquid Die Forging Production Line ke theknoloji ea morao-rao e kopanyang melemo ea ho lahla le ho etsa mekhoa ea ho etsa mekhoa ea ho etsa libopeho tse haufi-ufi. Mohala ona o mocha oa tlhahiso o fana ka melemo e mengata, ho kenyelletsa le phallo e khutšoane ea ts'ebetso, botsoalle ba tikoloho, tšebeliso e tlase ea matla, sebopeho sa karolo e ts'oanang, le ts'ebetso e phahameng ea mochini. E na le mochini o sebetsang ka bongata oa CNC liquid die forging hydraulic press, aluminium liquid quantitative quantitative system, roboto, le sistimi e kopaneng ea libese. Mohala oa tlhahiso o khetholloa ke taolo ea eona ea CNC, likarolo tse bohlale, le ho feto-fetoha ha maemo.

-

Vertical Gas Cylinder/Bullet Housing Drawing Line Production Line

The Vertical Gas Cylinder/Bullet Housing Drawing Production Line e etselitsoe ka ho khetheha tlhahiso ea likarolo tse bōpehileng joaloka kopi (e bōpehileng joaloka moqomo) tse nang le karolo e ka tlase e teteaneng, tse kang lijana tse fapa-fapaneng, lisilindara tsa khase le matlo a likulo. Mohala ona oa tlhahiso o thusa lits'ebetso tse tharo tsa bohlokoa: ho ferekanya, ho otla le ho taka. E kenyelletsa lisebelisoa tse kang mochini oa ho fepa, sebōpi se futhumatsang maqhubu a mahareng, lebanta la conveyor, roboto e fepang / letsoho la mochini, ho halefisa le ho phunya mochini oa mochini oa hydraulic, tafole ea li-slide tse peli, roboto / letsoho la mochini, ho taka mochini oa hydraulic, le sistimi ea phetisetso ea thepa.

-

Khase Cylinder Horizontal Drawing Line Production Line

Mohala oa tlhahiso ea moqomo o otlolohileng oa khase o etselitsoe mokhoa o otlolohileng oa ho etsa lisilindara tsa khase tse telele haholo. E sebelisa mokhoa o otlolohileng oa ho otlolla, o nang le yuniti ea hlooho ea mohala, roboto ea thepa ea thepa, mochine oa khatiso oa nako e telele o otlolohileng, mochine oa ho khutlisa thepa, le yuniti ea mohatla oa mohala. Mohala ona oa tlhahiso o fana ka melemo e 'maloa e kang ts'ebetso e bonolo, lebelo le phahameng la ho theha, ho otlolla nako e telele, le boemo bo phahameng ba ho iketsetsa.

-

Gantry Straightening Hydraulic Press bakeng sa Lipoleiti

Mochine oa rona oa khatiso oa "gantry straightening hydraulic hydraulic" o etselitsoe ka ho khetheha bakeng sa ho otlolla le ho etsa mekhoa ea lipoleiti tsa tšepe liindastering tse kang sefofane, ho haha likepe le metallurgy. Thepa e na le hlooho ea cylinder e tsamaeang, foreimi ea gantry e tsamaeang, le tafole e tsitsitseng ea ho sebetsa. Ka bokhoni ba ho etsa phalliso e otlolohileng holim'a hlooho ea silinda le foreimi ea gantry ka bolelele ba tafole ea ho sebetsa, mochini oa rona oa khatiso oa gantry o otlollang oa hydraulic o netefatsa tokiso e nepahetseng le e phethahetseng ntle le matheba a foufetseng. Moqomo o ka sehloohong oa mochini oa khatiso o na le ts'ebetso ea micro-movement ho ea tlase, e lumellang ho otlolla poleiti ka nepo. Ho phaella moo, worktable e entsoe ka li-cylinders tse ngata tsa ho phahamisa sebakeng se sebetsang sa poleiti, e leng ho nolofalletsang ho kenngoa ha li-blocks tsa khalemelo lintlheng tse itseng hape e thusa ho phahamisa lipoleiti.ifting ea poleiti.

-

Automatic Gantry Straightening Hydraulic Press bakeng sa Bar Stock

Mochine oa rona o ikemetseng oa gantry o otlollang hydraulic ke mohala o felletseng oa tlhahiso o etselitsoeng ho otlolla le ho lokisa thepa ea tšepe ea tšepe. E na le mochine o otlolohileng oa hydraulic o otlolohileng, mokhoa oa ho laola mokhoa oa ho lemoha (ho kenyeletsoa ho lemoha ho otloloha ha mosebetsi, ho lemoha ho potoloha ha angle ea mosebetsi, ho lemoha sebaka se otlolohileng, le ho otlolla mokhoa oa ho falla), tsamaiso ea hydraulic control system, le tsamaiso ea motlakase. Mochine ona oa hydraulic o feto-fetohang o khona ho iketsetsa ts'ebetso ea ho otlolla setoko sa tšepe, ho netefatsa ho nepahala le ho sebetsa hantle ho holimo.